Predictive Maintenance Assistant: Designing AI-Powered Insights for the Commercial Laundry Industry

Timeline

2024

Project Goal

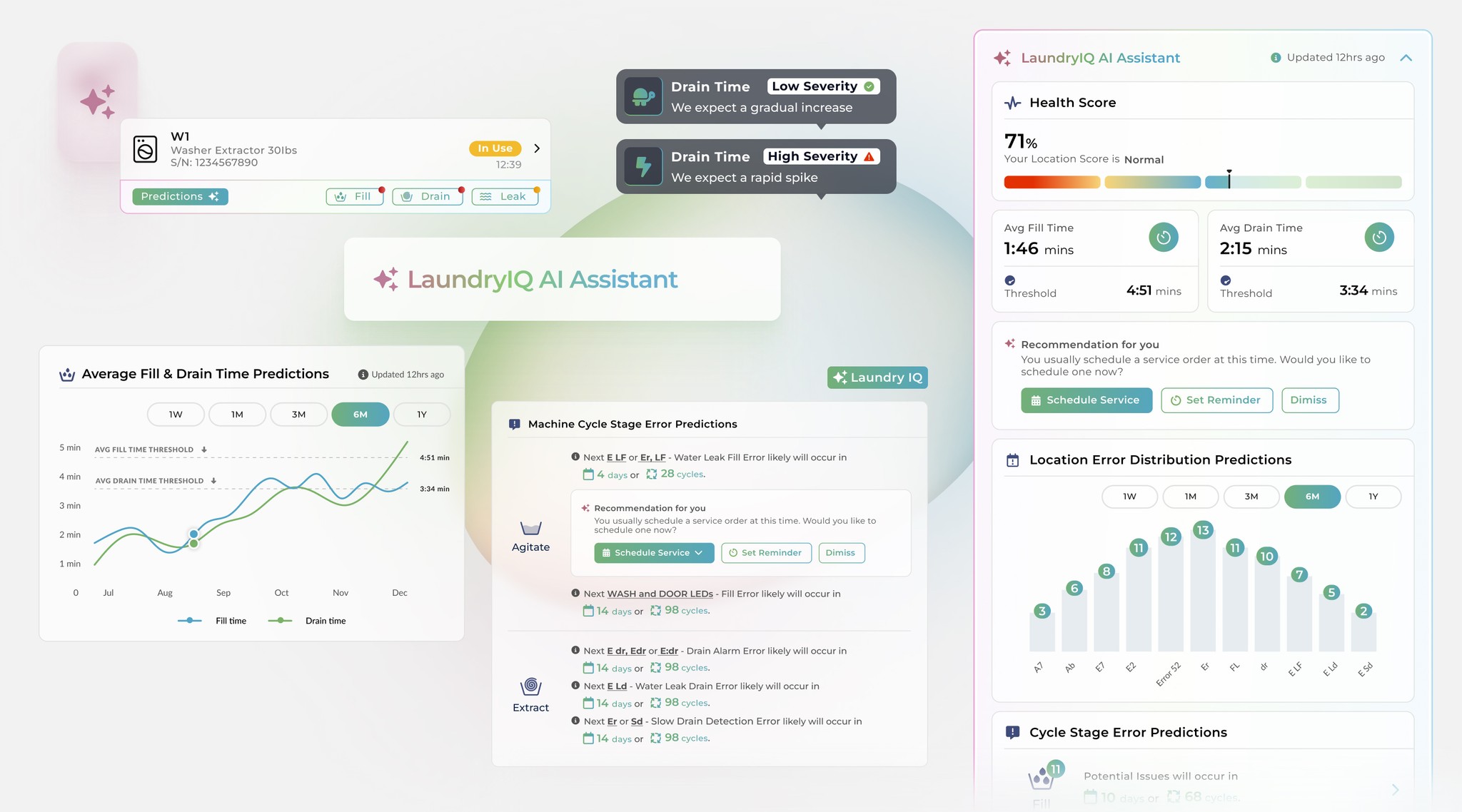

The client, a leading consumer and industrial products manufacturer, sought to improve operational efficiency by leveraging predictive maintenance. Existing AI models were unreliable. The goal was to design a predictive maintenance feature that translated AI outputs into actionable workflows, enabling operators to anticipate failures, reduce unplanned downtime, and optimize resource allocation.

User Goal

Maintenance operators required real-time visibility into at-risk machines, clear reasoning for predicted failures, and actionable recommendations. so they could act in advance to minimize machine downtime.

Solution & Impact

Our team built a predictive maintenance feature within the Fleet dashboard. Integrated real-time and historical data to generate actionable AI predictions. Developed interfaces that highlight at-risk machines, provide AI-driven recommendations, and trigger notifications. The feature allowed operators to act proactively, reducing downtime, improving maintenance scheduling, and supporting the client’s operational efficiency objectives.

My Role

Owned full design execution from concept through delivery. Translated evolving AI outputs and technical constraints into actionable predictions and recommendations valued by users and the business. Conducted user and stakeholder interviews, defined user flows, and produced high-fidelity prototypes. Directed interaction and visual design. Collaborated with AI/ML engineers and business stakeholders to ensure technical feasibility and usability.

Reach out to know more!

Predictive Maintenance Assistant: Designing AI-Powered Insights for the Commercial Laundry Industry

Timeline

2024

Project Goal

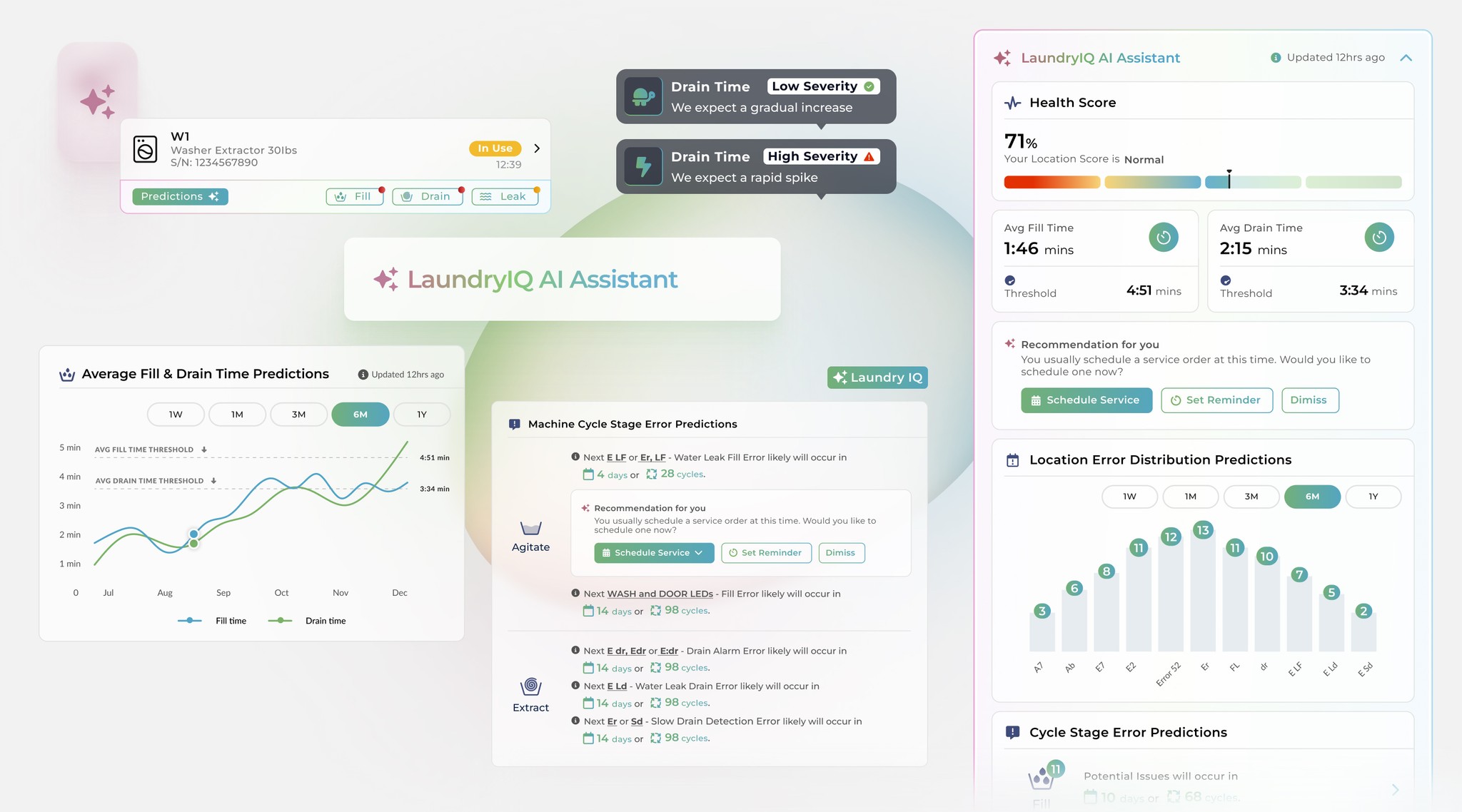

The client, a leading consumer and industrial products manufacturer, sought to improve operational efficiency by leveraging predictive maintenance. Existing AI models were unreliable. The goal was to design a predictive maintenance feature that translated AI outputs into actionable workflows, enabling operators to anticipate failures, reduce unplanned downtime, and optimize resource allocation.

User Goal

Maintenance operators required real-time visibility into at-risk machines, clear reasoning for predicted failures, and actionable recommendations. so they could act in advance to minimize machine downtime.

Solution & Impact

Our team built a predictive maintenance feature within the Fleet dashboard. Integrated real-time and historical data to generate actionable AI predictions. Developed interfaces that highlight at-risk machines, provide AI-driven recommendations, and trigger notifications. The feature allowed operators to act proactively, reducing downtime, improving maintenance scheduling, and supporting the client’s operational efficiency objectives.

My Role

Owned full design execution from concept through delivery. Translated evolving AI outputs and technical constraints into actionable predictions and recommendations valued by users and the business. Conducted user and stakeholder interviews, defined user flows, and produced high-fidelity prototypes. Directed interaction and visual design. Collaborated with AI/ML engineers and business stakeholders to ensure technical feasibility and usability.

Reach out to know more!

Predictive Maintenance Assistant: Designing AI-Powered Insights for the Commercial Laundry Industry

Timeline

2024

Project Goal

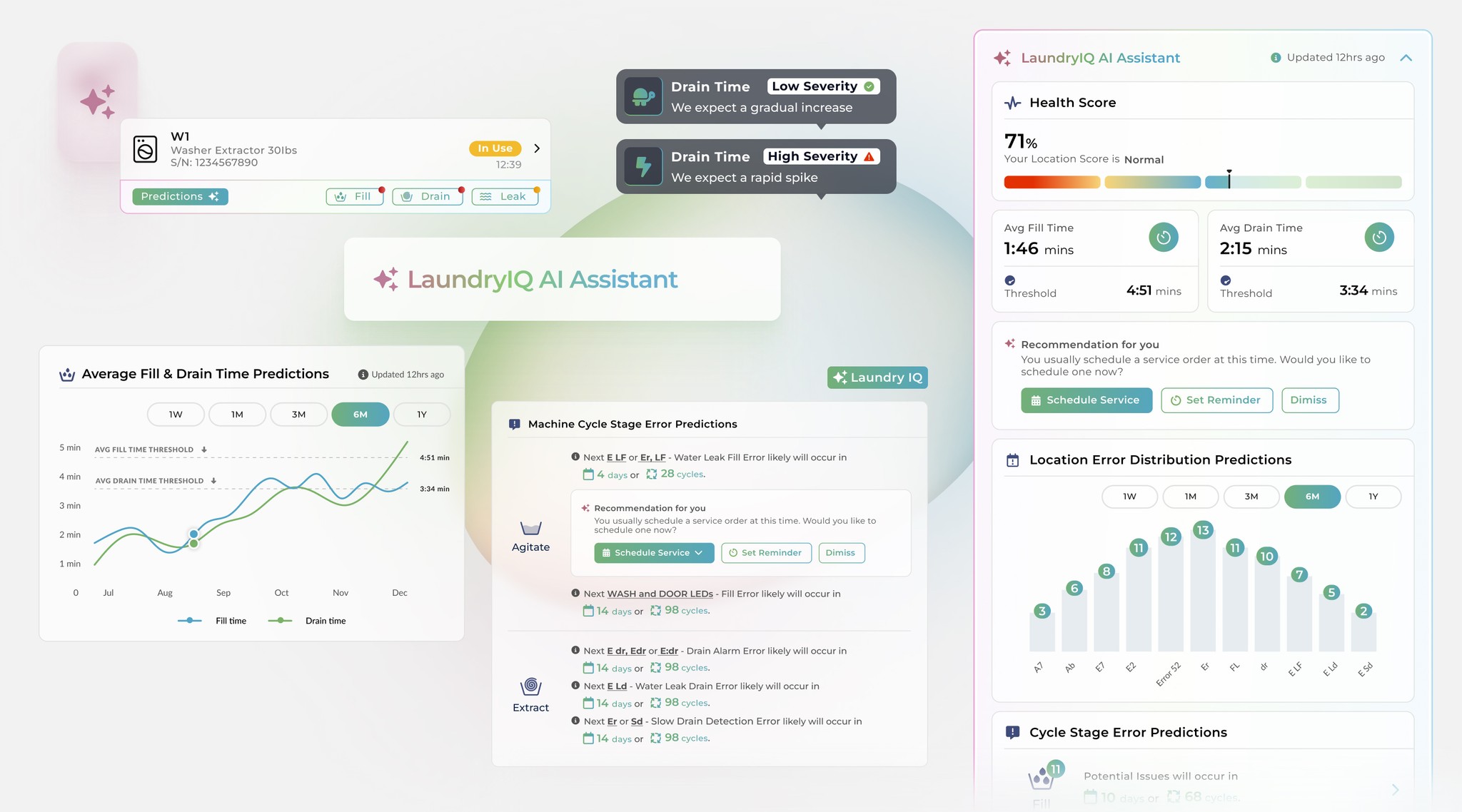

The client, a leading consumer and industrial products manufacturer, sought to improve operational efficiency by leveraging predictive maintenance. Existing AI models were unreliable. The goal was to design a predictive maintenance feature that translated AI outputs into actionable workflows, enabling operators to anticipate failures, reduce unplanned downtime, and optimize resource allocation.

User Goal

Maintenance operators required real-time visibility into at-risk machines, clear reasoning for predicted failures, and actionable recommendations. so they could act in advance to minimize machine downtime.

Solution & Impact

Our team built a predictive maintenance feature within the Fleet dashboard. Integrated real-time and historical data to generate actionable AI predictions. Developed interfaces that highlight at-risk machines, provide AI-driven recommendations, and trigger notifications. The feature allowed operators to act proactively, reducing downtime, improving maintenance scheduling, and supporting the client’s operational efficiency objectives.

My Role

Owned full design execution from concept through delivery. Translated evolving AI outputs and technical constraints into actionable predictions and recommendations valued by users and the business. Conducted user and stakeholder interviews, defined user flows, and produced high-fidelity prototypes. Directed interaction and visual design. Collaborated with AI/ML engineers and business stakeholders to ensure technical feasibility and usability.

Reach out to know more!

Predictive Maintenance Assistant: Designing AI-Powered Insights for the Commercial Laundry Industry

Timeline

2024

Project Goal

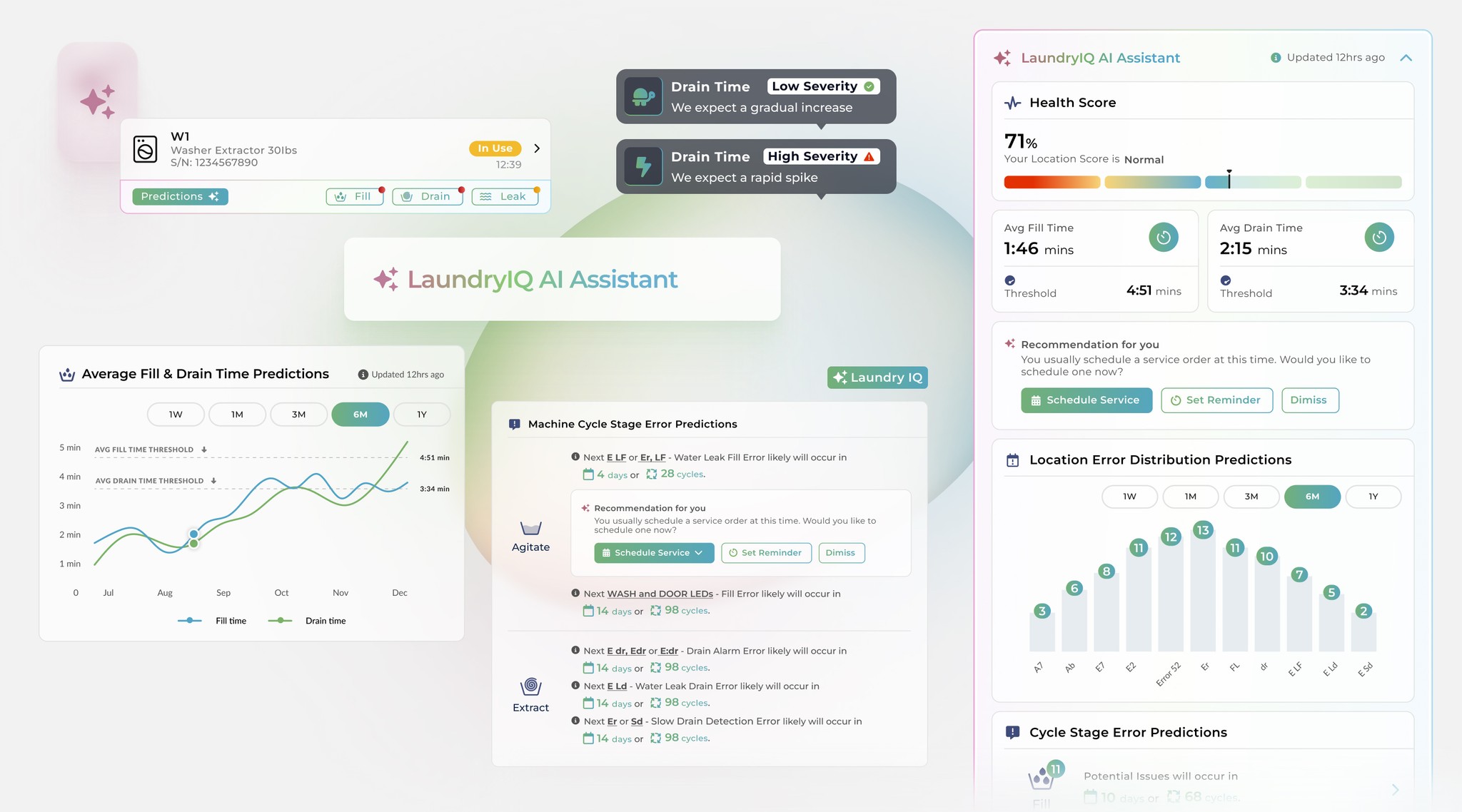

The client, a leading consumer and industrial products manufacturer, sought to improve operational efficiency by leveraging predictive maintenance. Existing AI models were unreliable. The goal was to design a predictive maintenance feature that translated AI outputs into actionable workflows, enabling operators to anticipate failures, reduce unplanned downtime, and optimize resource allocation.

User Goal

Maintenance operators required real-time visibility into at-risk machines, clear reasoning for predicted failures, and actionable recommendations. so they could act in advance to minimize machine downtime.

Solution & Impact

Our team built a predictive maintenance feature within the Fleet dashboard. Integrated real-time and historical data to generate actionable AI predictions. Developed interfaces that highlight at-risk machines, provide AI-driven recommendations, and trigger notifications. The feature allowed operators to act proactively, reducing downtime, improving maintenance scheduling, and supporting the client’s operational efficiency objectives.

My Role

Owned full design execution from concept through delivery. Translated evolving AI outputs and technical constraints into actionable predictions and recommendations valued by users and the business. Conducted user and stakeholder interviews, defined user flows, and produced high-fidelity prototypes. Directed interaction and visual design. Collaborated with AI/ML engineers and business stakeholders to ensure technical feasibility and usability.

Reach out to know more!